ইমেল বিন্যাস ত্রুটি

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

খবর

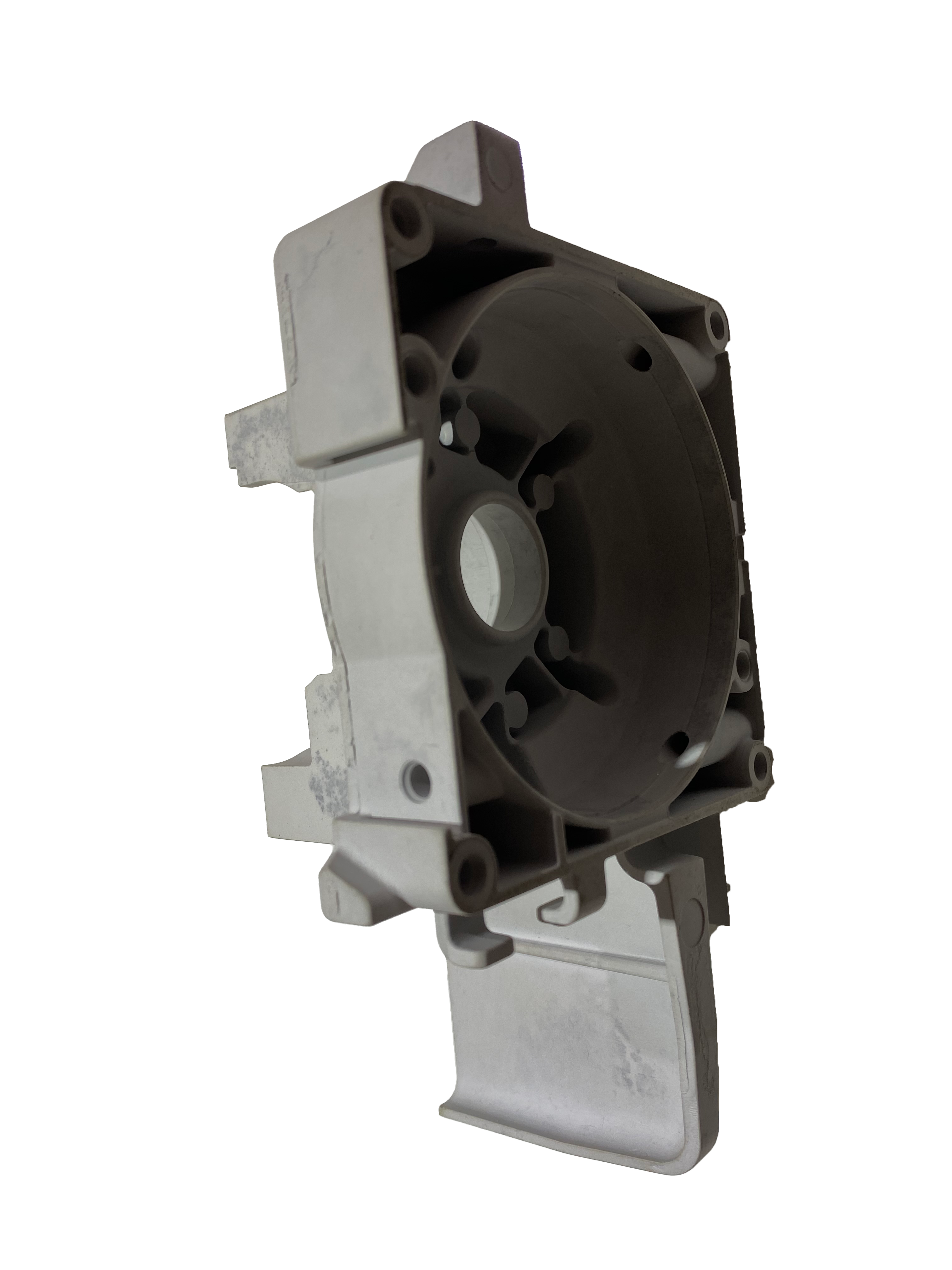

Lost Wax Casting for Bronze Crafts

We use the lost wax casting process to provide high-quality copper casting sculpture customization services. Whether your sculpture is miniature or huge, we can process brass, bronze, copper, silver and other materials, if your sculpture needs other metals, please contact us for details.

Copper carving handicrafts are common in our daily life. The production of copper carvings generally requires several important processes such as metal smelting, forging, carving, gold plating, polishing, and red coloring. The process is more complicated, and the craftsmanship is also very elegant.

There are two main methods of casting copper carving crafts, namely lost wax and mold method. Mold method: widely used, large-scale bronze sculptures are generally cast in parts, and then connected into a whole. Copper melting method: Using the moldless and controllable melting and casting process, "no mold" makes the copper liquid naturally smooth and unsharp; "controllable" makes the copper liquid melt under the artist's control. These two sculpture techniques are often used in our daily sculpture manufacturers, which also need to be known and understood by all of us.

What is lost wax casting?

Lost wax casting is also known as investment casting. The lost wax process enables any object that can be modeled in wax to be accurately turned into metal. The wax patterns are carved from special sculptural wax designed to preserve the fine details of the sculpture. Most fine jewelry in gold and sterling is made with lost wax castings because it produces the highest level of detail. According to the characteristics of the product, we use different casting methods, such as plaster mold lost wax casting, silica sol lost wax casting.

Gypsum mould lost wax casting

Gypsum lost wax casting is a lost wax casting process similar to silica sol lost wax casting, except that the molding material is gypsum instead of sand and silica sol, sand casting is the most expensive. When an excellent surface finish and good dimensional accuracy are required, plaster mold casting can be used, with a minimum possible cross-section of 0.6 mm (0.024 in). We use it for castings weighing from 30 grams (1 ounce) up to 45 kilograms (99 pounds).

It is used when excellent surface finish and good dimensional accuracy are required, but it is the most expensive casting process.

Silica sol lost wax casting

The silica sol lost wax casting process uses silica sol zircon sand as the molding material and can withstand temperatures up to 2000 degrees. This molding material is expensive, and silica sol investment castings have good size (larger sculptures can be cast than plaster casts) and surface quality.

Conclusion

With the development of modern intelligence, the production process of bronze sculpture is also constantly changing. For example, the reformed non-polluting workshop has achieved dual control of "gas" and "water" to ensure pollution-free discharge. Another example is the production link, which often combines casting and forging, which constitutes a new demand under the new situation.

For more information about lost wax casting copper,direct lost wax casting,lost wax casting bronze sculpture, we are glad to answer for you.